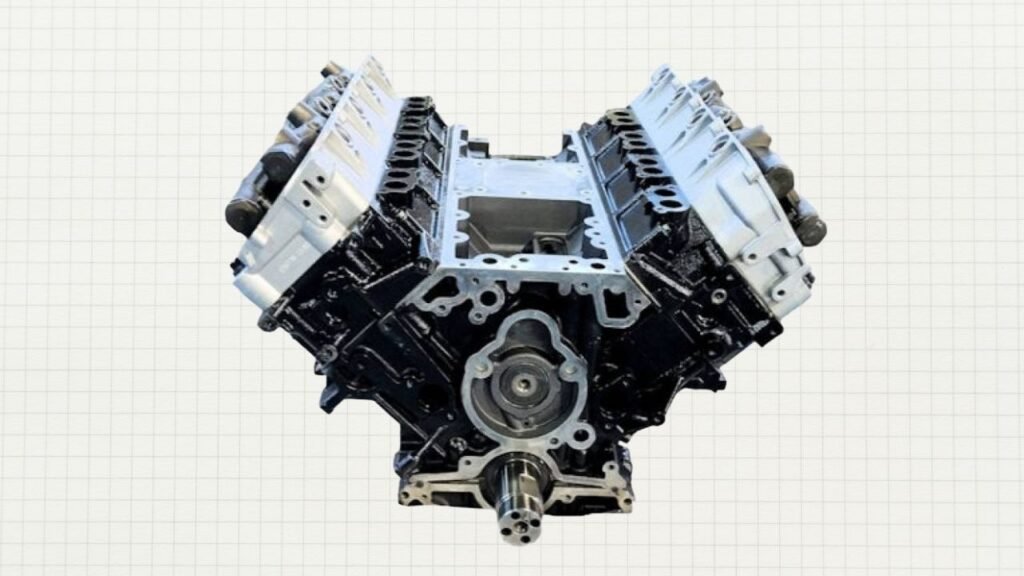

The Ford 6.0L Power Stroke, was introduced in the 2003 in collaboration with Navistar. This was mainly designed to meet newer norms and featured modern techs of that time like geometry turbo, digital fuel injection, four valves per cylinder, and an EGR system. You can find this mainly in Ford’s F-250 to F-750 trucks. Following is the guide to 6.0 powerstroke firing order.

6.0L Power Stroke Firing Order: 1-2-7-3-4-5-6-8

The Ford 6.0L power stroke has firing order of 1-2-7-3-4-5-6-8, this improves power delivery making it much smoother and have balanced operations. Best part of this is that this sequence spaces combustion evenly at 90-degree intervals which makes proper fuel injection.

Comparison with other Ford engines:

- Small-Block V8s (289, 302): 1-5-4-2-6-3-7-8 351

- Windsor / Modular V8s: 1-3-7-2-6-5-4-8 7.3L

- Power Stroke: 1-2-7-3-4-5-6-8 (same as 6.0L)

Notably, the 6.0L has same order as of 7.3L power stroke engine. Despite being two different engines they share similar firing order.

Cylinder Numbering and Configuration

I like the numbering system used in the 6.0L power stroke engines compared to conventional V8s. It is simple, Bank 1 is located on the passenger side and it contains all the odd numbers like 1-3-5-7. Then Bank 2 is on the drivers side which contains all the even number cylinders like 2-4-6-8.

This engine has firing order of 1-2-7-3-4-5-6-8 making it powerful and less vibration engine on any RPM. This sequence is highly recommended on the crankshaft design with specifically arranged journals and a camshaft profile that optimizes valve timing for each cylinder.

Common Problems with the 6.0L Power Stroke

- EGR Cooler Failures – One of the most common problem with 6.0L Power Stroke is that it causes cracks due to coolant starvation. This diminishes the performance specs over the time.

- Head Gasket Failures – 6.0L Power stroke has also seen head gasket failure which leads to weak torque and can cause gasket blowouts.

- Turbocharger Issues – We have seen complaints of owners having corrosion and carbon buildup made variable-geometry vanes stick. this obviously reduces efficiency.